Page 564 from the link above:

The blades are made in pieces, and are joint using Crystic Crestomer 1152 PA, which is a carbon and glass fibers adhesive. The design, which is not applicable for HAWT, lowers the costs in manufacturing and transportation compared to a one-piece blade.

Below there is also an analysis of the potential of scaling for VAWT offshore:

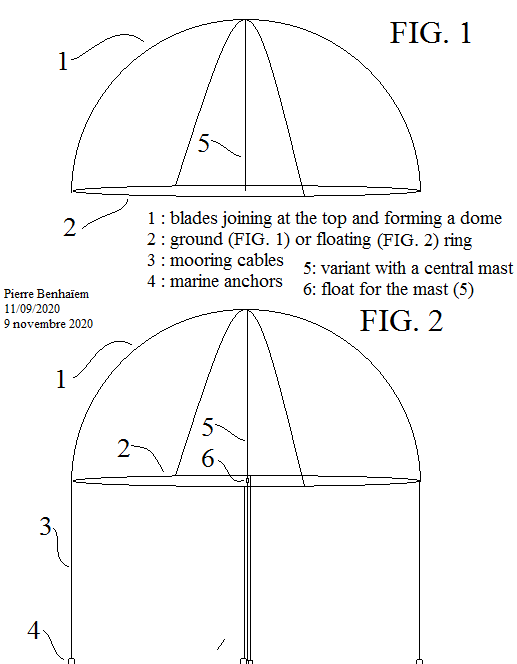

I think that perhaps the rotary part of a giant VAWT could be a carousel, allowing to benefit from both higher speed for the generator, and a more resistant and stable rotary basis, as shown on the sketch below: