Noted. This just came up, I had expected the other topic to stay more theoretical.

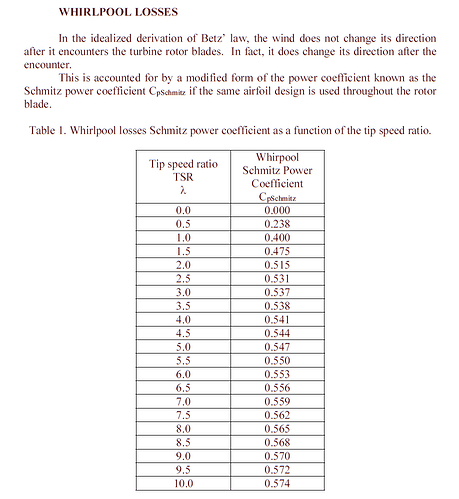

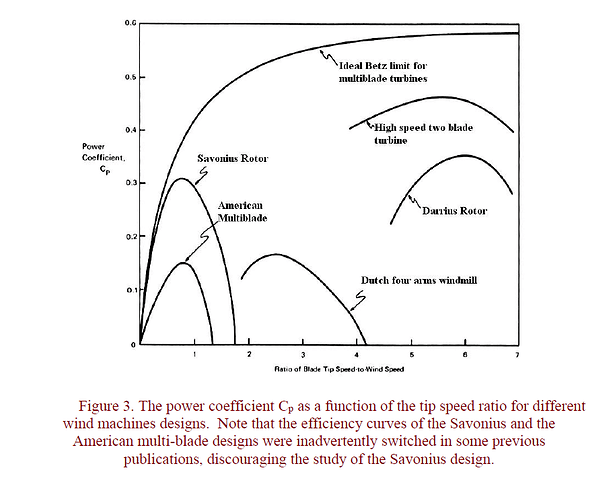

The paper gives some graphs and tables:

The table and the graph agree I think I shouldn’t try to lower de TSR to much lower than 2. At a TSR of 2, the efficiency looks to be still around 93 percent of the efficiency of a turbine with a TSR of 6.5 (0.515/0.556).

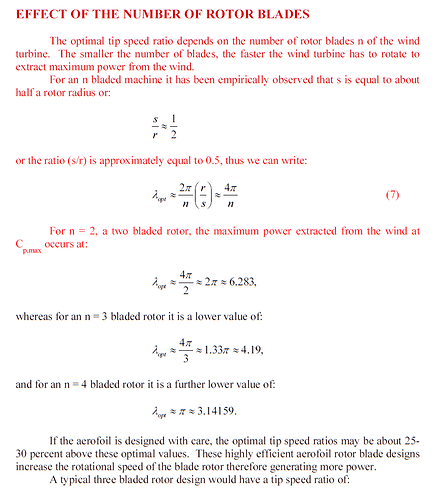

I don’t know how applicable the “empirical observation” that s/r is 1/2, to my design, as my design, like those of @Rodread and @someAWE_cb doesn’t have a hub. Ignoring that, it becomes easy to calculate optimal TSRs:

For 5 bladed rotors: 4pi/5 = 2.5; for 6 bladed rotors, 4pi/6 = 2.1; for 7 bladed rotors, 4pi/7 = 1.8, for 8 bladed rotors, 4pi/8 = 1.57.

To me it looks like I should aim for 6 or 7 blades. 4 blades would have the tips moving at 30 m/s (108 km/h) in 10 m/s wind, that’s too fast.

What would be some things to look out for when designing a 6 or 7 bladed rotor? Maybe it becomes easy for the TSR to get too low? Maybe the band of windspeeds that it would work efficiently in is very small? I’d like to optimize the thing to work well in 8-12 m/s wind.