https://www.compositesworld.com/articles/reimagining-wind-blade-design

Traditional wind blade design — glass fiber laminate shell over a balsa/foam core, surrounding a composite shear web — have done an admirable job of addressing these requirements. But as wind turbine blades get longer, wind turbine manufacturers are looking for ways to reduce materials use, reduce weight, decrease costs and increase manufacturing efficiency.[…]

The design ACT Blade came up with is, actually, a familiar one to anyone who understands aeronautics. It is comprised of a spar to which is attached a series of ribs. Overwrapping this spar/rib structure, in tension, is a technical textile — called a “sock” — that provides the aerodynamic surface the blade requires for wind capture.

Perhaps this method could also apply to rigid AWES or to larger propellers for @Kitewinder or for SuperTurbine ™.

3 Likes

Similarly … Flexing sail leach tech dramatically changed how smoothly a windsurfer sail responds to gusts.

Very cool approach … I’d worry how much the sliding of the sock material over the spar will cause wear.

My sock get holes from…

Also I’m not volunteering for the job of downhaul puller who has to get that sock tight enough on the spar. Hurts my little handies enough getting a sail pulled down enough on a windsurfing mast.

The robots and deform-able sail tables used for laying the weave of high end yacht sail manufacture are likely more accurate but more expensive than this sock approach …

The sock could likely be made using a braiding machine like

is possibly like the

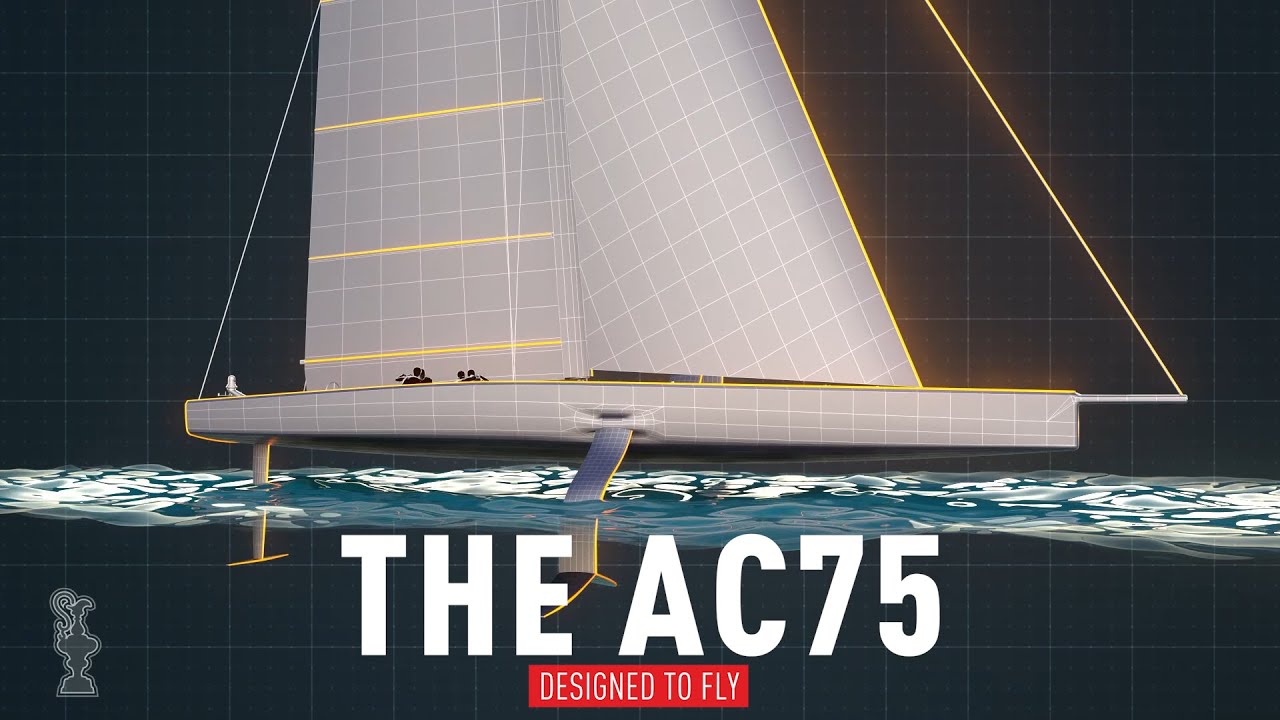

The high end sails are done like (Mind you this is only the single sheet sails… The Americas cup AC75’s have something which looks more akin to what @PierreB shared above)

2 Likes

I wish this article has more specifics - kind of hard to understand the details exactly from this brief read.

There was a big buzz a few years ago, that some ladies at GE Wind were developing a similar approach to this one. I attended a Windpower trade show in nearby Las Vegas and had the good fortune to be talking with GE Wind’s director of international research (or some equivalent title). When I asked him about the fabric-covered blade research, he seemed dismissive, as though he did not take it seriously. So far, years later, I have not heard about any results from that GE effort. Sounds good though. I hope this effort has better success. One thing people new to wind energy seem to have trouble understanding is how severely blades are beaten to death. I’m in the process of repairing some right now for the most popular 10 kW turbine, and it is a lot of work, and a lot of head-scratching, entailing considerable time and some cost…

1 Like

Just out of curiosity @dougselsam : how do you think a soft kite could take this abuse… say for three years before replacement, and assuming the fabric is UV safe…

This set of twin skin sails are the highest performance ones on the planet I’d recon…

OMG I’m obsessing over AC75 class

1 Like

It would be a great achievement. The flexible wing would be competitive.

Good question. I don’t know the answer. It would have to depend on the effectiveness of whatever solution is implemented. Obviously it would be a challenge to overcome.

1 Like

Fabric wings fall into two categories: pure flexible wing such like ram or single skin kites, and wings with a frame such as hang gliders. When the frame forms a volume, we have profiles such like the textile ACT blades. The wings in the second category could perhaps have a higher lifetime, but as for a single skin kite made from thick fabric.

Unlike textile kites with a frame, pure flexible kites undergo wear by flapping and more variations of loads during operations such like crosswind flight and reel-in/out phases if yo-yo method is used.

In the other hand fabric can undergo tension and wear close to the frame.

Tests and feedback are desirable.

I had reported on the old forum years ago, when GE Wind had a similar program, also run by women, to develop a fabric-covered blade. (imagine all the financial “incentives”.) This was endlessly cited as an example of how great cloth was for wind energy, by the most vocal and extreme, of the incurable, soft-kite-worshipping, lifetime-newbies associated with the old site.

At a wind energy trade show in Las Vegas, I found myself talking to their international head of research, and he was quite dismissive of the concept and the entire cloth-covered blade program, telling me there really wasn’t anything there to get excited about.