There was a recent discussion on making wind turbine towers. Here is my submission.

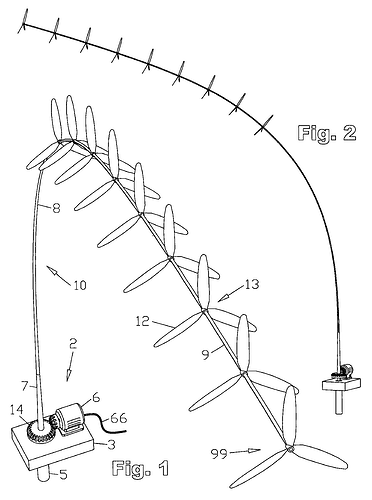

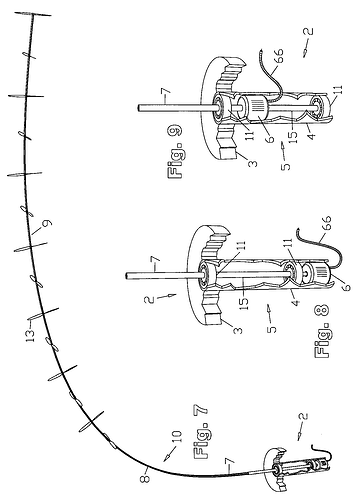

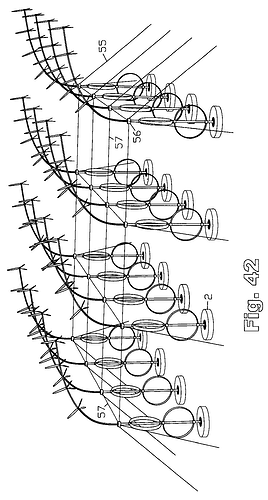

Let’s imagine a symmetrical airfoil as a wind turbine tower. To relieve stress on the base bearing and tower, guy cables ride along circular tracks that get added to the tower at certain heights. This is the novel concept.

Let’s construct the tower out of wood like Modvion does, using the same construction techniques.

I think it makes sense to use a downwind rotor to act as an additional vane and to lower its stiffness requirements. This rotor could potentially be partly tensile, or airborne.

Benefits would be:

- As a wind turbine tower is loaded mostly in line with the wind from the wind loading on the tower (which here is reduced by an order of magnitude) and the pull from the rotor, this design allows you to make it stronger (wider) in that direction.

- Upwind wind turbine blades need to be made very stiff to prevent tower strikes, and downwind rotors suffer from the tower wake, this design solves or reduces both problems.

- No, or reduced, need for a motor to rotate the tower relative to the wind as the airfoil profile of the tower acts as a vane.

- The, I think, novel concept of guy wires riding along circular rails lowers the strength requirements on the base and the tower.

- It could be possible, with the added strength in one direction of the tower, to assemble it horizontally, together with the nacelle and blades, and hoist it vertical for installation, or lower it for maintenance.