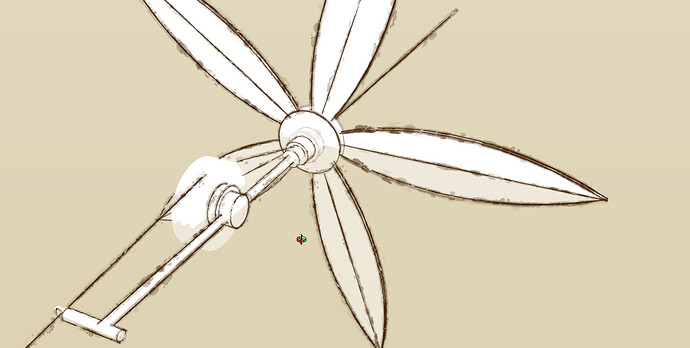

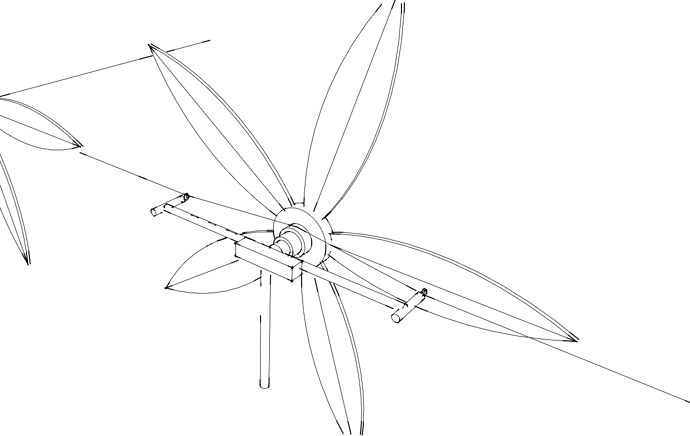

Here is an idea I had after reading some discussion on the forum:

You see the tight side of a rope drive going from bottom to top, it goes around the pulley once or as many times as needed to not slip and then goes through a hole (not drawn) in the hub of the rotor. The pulley has 2 grooves, one for the rope drive, another for a belt or rope or some other thing so it can be driven by the pulley (not drawn) on the hub of the rotor. Also not shown for example are a vane, a generator, some small number of the same rotor on the same line, a lifter kite, and the slack side of the rope drive.

The thing will not work as drawn as it is missing elements, but this is the main idea.

You can imagine it being applied to torque transfer methods, the product being developed by @Kitewinder, and others.

Drawbacks could be increased wear on the rope from more contact with pulleys and the rope rubbing on itself, and efficiency losses from going through more pulleys. You can think of more. I’d be interested to read physics based comments saying why it can or cannot work (efficiently).

If you can control the rotation of the rotors you should be able to maintain the height and distance from each other of the rotors. If you can’t, perhaps you can vary the rpm of your generator to do that. In that way it is similar to the Brainwhere promise.