https://www.empa.ch/web/s307 intended to fill the kite with helium. Indeed I think a small electrolyser and a 1 m² PV would be enough to keep the LEI kite inflated, even if the available volume is likely not sufficient to keep it in the air. However with the process I describe, the pressure will be that of the ambient air, no more, except if we add a compressor or… a pump, involving in additional weight and cost.

Another possibility: a central lifter kite-balloon with PV-electrolyser on board and dancing kites (possibly comprising also PV-electrolyser) around.

Note also the link for a new (but not still available) technology to produce directly hydrogen with solar on

Plus 100 kg of water to make the 120 m³ of hydrogen, by year. This can be still workable, but the process to produce hydrogen directly could be better if it becomes available. Another possibility is waiting for large storms (1/month?) to recovery the system and refuel water (about 10 kg). Another possibility is collect water in flight (rain, dew).

I believe collecting water from the air should be possible. Also adding a compressor is probably not much harder than making hydrogen gas in-air

H2 loss will be 100% in a bad storm, without a hangar or required deflation. Slow H2 leakage also corresponds with increasing air contamination and unacceptable explosion risk, and still adds greenhouse gas.

Harvesting water vapor aloft instead of raising water will be comparatively marginal.

Indeed the process of endosmose is the main obstacle.

Endosmose is also a problem with He also, where air contamination is only parasitic of lift. The gas gets replaced in bulk, sooner if lift-force operating margin is accordingly smaller.

A new balloon is effectively gas-tight but delicate, and soon develops tiny leaks over time that relentlessly dilute the lifting gas, with no easy solution. Thermal cycles and general envelope motions help push lifting gas out and air in.

I used to store micro-blimps in a dark quiet stable temperature room, nose-up, and only replace the bottom gas, with its higher air content, from the tail-cap.

1 Like

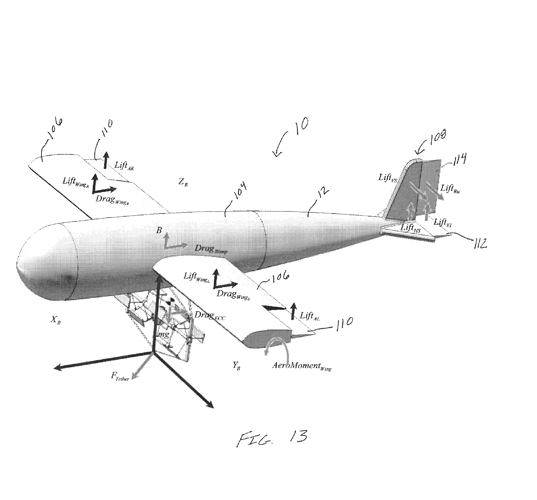

https://patents.google.com/patent/WO2013049732A1/en?oq=US20140246862A1

(This is not a patent search, just something I stumbled across)

I like how they went to all this effort then stuck a VAWT turbine below it (I would assume a HAWT turbine would be better for this purpose?). Also no mention of gas production onboard.

“…a substantially airtight chamber for storing lighter-than-air gases”.

The chamber must be airtight enough to avoid the process of endosmosis leading to an “unacceptable explosion risk” as @kitefreak rightly indicates, while being still light enough.