Authors: Joep Breuer, Rolf Luchsinger, Roland Schmehl. Text and PDF available on the link below:

I find this very interesting and innovative. But, the wings produced don’t seem very aerodynamically effective.

I think maybe take a step back to consider 3D inflated foils with internal structures. I am unsure if Jaquard weaving is the main takeaway here.

There was a company showing drop stiched kites at AWEC 2021.

From the book of abstracts at https://repository.tudelft.nl/islandora/object/uuid:696eb599-ab9a-4593-aedc-738eb14a90b3?collection=research

@tallakt I have tried may times to find out how dropstich fabric is made without suksess. I have only come as far as finding that the machine has hundreds of parallell needles to make the vertical threads, but have not found out how they make the slack that is required to maintain the correct thickness when the fabric is inflated. I even tried to ask ChatGPT without getting any closer to how it works.

Seems the SUP and the wing from Enserink use a different process, the threads in the SUP seem a lot denser.

I seem to remember that the wing section at AWEC was hand made but work was being done to automate production.

Seems creating the machine is almost as hi-tech as AWE itself. So that could be a reason to stick to what already exists

Ok. That is not dropstich fabric. It looks like they are just ultrasonic welding a ribbon (probably ripstop nylon with a TPU coating) to the two skins of the wing. A novel concept, but i don’t think it will be nearly as strong as a true dropstich fabric, but maybe it don’t need to be if they are using lower pressures than is used in SUP’s and other stuff that use dropstich fabric. But lower pressures also mean less stiffness and more fluttering and more wear on the fabric.

Also the dimples they get where each ribbon is attached will not be there one true dropstich fabric, because the threads are much closer than the ribbons on this concept. I have seen these dimples on some air mattresses for camping and start to wonder if they are made the same way?

Here is more info on dtop stitching. Seems base material is preproduced in a fixed thickness, then made to whatever shape necessary.

I am not sure if that process would be suitable for a wing. Also in huge sizes they would be relatively softer.

The Enserink design though is more customizable in thickness of the profile and holds more promise to me.

Hi @Storm_Eagle, thanks for your insight and explanation, we only discovered this thread today. Here’s my belated reply:

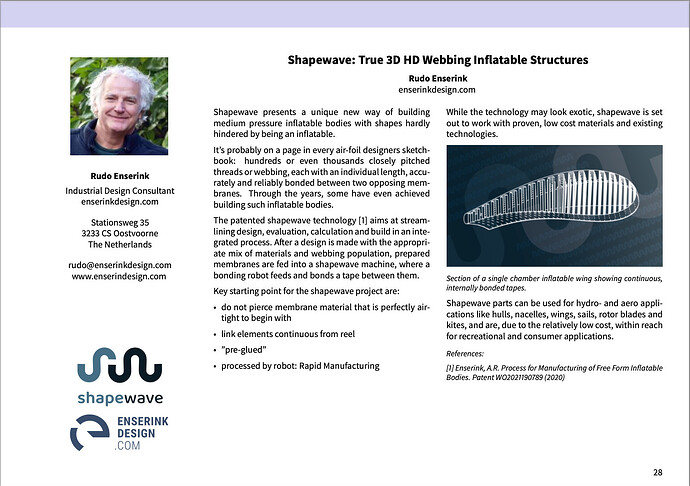

Our tech is indeed not dropstitch. However, your assumption on the materials and strengths may apply for the hand made sample in the picture, not so much on what we’re tinkering on for commercial use. Our webbing/weld/membrane construction has a breaking load of about 160N/cm¹, so with close enough pitching we’d easily reach SUP level pressures of about 1 bar and have plenty safety margin (well north of factor 5). However brilliant our tech may be, we’re still dealing with inflatable parts so the smoothness of the inflated part will always be depending on how many webs you want to put inside. Our software is really helpful in determining material mix, webbing patterns, weight, build time, cost,

For updates on our developments feel free to follow our LinkedIn page

cheers, Rudo

Welcome to the forum @Rudo ,

Thanks for the information.

It seems to me that SUP and other drop-stitched products (possibly circular in shape) are made up of thousands of threads of the same length connecting the two parallel sides of the fabric.

To my knowledge, drop-stitch technology is not (yet?) designed for profiled shapes such as kite wings, unlike your technology which implements a webbing pattern allowing the thickness of the profile to be graduated?

See also Historical Perspective on Inflatable Wing Structures

https://arc.aiaa.org/doi/abs/10.2514/6.2009-2145

thank you @PierreB , in answer to your question: we can weld the webs wherever we want so for use of double curvature (by using multiple panels in a membrane), convex, concave, cambered (assymmetric) shapes, bring it on!

Drop stitch is mostly flat panel indeed, although there are some very interesting developments out there as well. shapewave however will be lighter and way more acrobatic in terms of shapes.

Did not the Goodyear Inflatoplane use dropstitch fabric to make the wings of the plane in the 50’s?

Yes, thank you for the information.

Inflatable, rubber, monoplane. Powered by a single, two-stroke, 42-hp, Nelson engine mounted behind the pilot and above the wing after inflation. Two-seat variant has a 60-hp McCulloch engine. Somewhat like a giant inner-tube. Structural integrity was retained in flight with forced air being continually circulated by the motor, and required less air pressure than the average auto tire.

https://ids.si.edu/ids/deliveryService?id=NASM-A19740156000cp01