Looked pretty good Rod.

Interesting damage.

Nearly every node of the hexagonal framework took damage.

Just over half the time the printed fuselage cuff burst open, mostly at the trailing edge.

The other times it was the tubes which broke… more at the leading edge.

So the balance of strength needed might not have been too bad.

For that brief few seconds it flew ok… Maybe I should have set the back line elevation higher for more autogyro lift…?

The big lesson of course is… Use more lift and more reliable lift then just don’t crash the damn thing instead.

Yet again, the foam blades and lines are all fine… They’ll be recycled into the next version.

This is a good suggestion for stability but the main problem was loss of tension.

I use a very small lifter.

In the drawing it kinda looks like the 2 extra lifters are at the side … Good as long as the wind is going into the drawing.

A lattice or top net of lifters which surrounds the main lifter, close to the horizontal plane at lift kite altitude, would allow the wind to change direction.

Just need to tweak the feet lengths a bit to keep everything nice and tight relatively.

I was under the impression that your lifter was chasing left and right, something that could make lack of lift more serious. Nevermind if I’m far off, I dont have all your observations to base my suggestions on.

(I won’t need to re-look at the video…) You’re bound to be absolutely right @tallakt , it will have been hunting in this test, and a few others… Not massively with such a long tail … but any hunting won’t help a static lifter.

I was thinking of … later down the line it would be good if they were made isotropic AND stable.

Hunting wouldn’t be such a problem if the lifter was higher up. It could even be looping. e.g. I could use something with a bit of control … a yo-yo design or a Makani type as my lifter

Another big change is coming to Daisy designs and testing…

It will be being done from Shetland.

My wife has a new job there, and we’ll relocate.

Time scales as you can imagine are a bit flexible right now

I wish you the best with the move, Rod.

Virus may affect schedule? Will you have a field for testing?

Here’s to hoping for a happy and successful move to a new island for Rod.

I looked up Shetland and find the island is

“windswept and rugged”, no trees, few people - like 28,000? - and you’ll see 100 identical articles explaining how doctors there prescribe outdoor activities to patients for stress, high blood pressure, type 2 diabetes, etc., but that many, of course, already take advantage of the great outdoors for health and fun. I wonder if they caution patients to be careful not to get blown off the island when the wind gets strong. Funny how 100 “journalists” can suddenly all write the same article at the same time. Like the articles you can still find “covering” Magenn and Altaeros.

Rod, ever notice how the windier the place, the fewer trees to get in your way, and the fewer people who want to live and build there? Kind of like the Mojave desert here. Still, as more people discover the charm of these “remote” places, more people move there and they become less remote.

Today watching the Bloomberg channel my girlfriend asked me “What is Brent Crude?”. Well I told her, then looked it up to double-check and found it all goes to Shetland:

"Crude oil is by far the world’s most important energy source and the price of oil therefore plays an important role in industrial and economic development. There are different types of crude oil. The most important type of crude oil used in Europe is Brent Crude, named after the North Sea oilfield where it is extracted. Brent Crude is a particularly light crude oil which is carried from the North Sea to the Sullom Voe Terminal on Mainland, Shetland by an underwater pipeline. From there, the crude oil is transported by tanker.

LINK: https://markets.businessinsider.com/commodities/oil-price

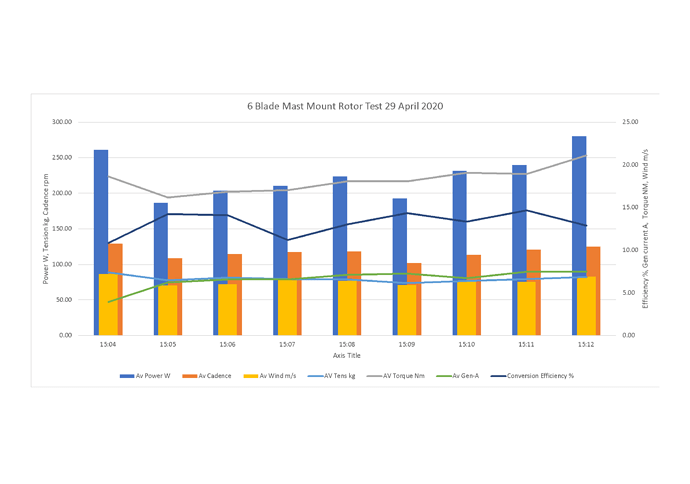

A wee video from yesterday’s test

It looks like Daisy with only three blades delivers a similar power (over 1 kW with wind speed being roughly 9.5 m/s as mentioned on a comment of the video below), all things being equal. Perhaps a part of the high pull could be converted into more torque?

@Rodread, do you plan to implement again two rotors with 3 rigid blades each,to obtain a possible far higher power than for the initial two rigid rotors (600 W if I remember correctly)? Or a larger rotor with the 6 blades?

Pretty sure the 6 blade rotor is higher power than any 3 blade rotor has been…

A lot more test and analysis needed to be sure.

My first plan is to get another viable TRPT made.

A better one.

Sorry, trying to remember what TRPT stands for? Torque-responsive pet turtle?

Looks like you’ll be at a standard tower-based wind turbine in no time! :))) Just kidding. I liked the video with the 6 blades.

Did you start using rods rather than rings for the innermost part of the shaft?

The acronym TRPT Tensile Rotary Power Transmission came from University of Strathclyde work.

When I use it…I sound real brainsy and academic like.

Yeah I had a mix of rods and rings in the TRPT low end… Interestingly it was the rod parts which failed.

This could be for several good reasons… Most likely is that, in the test, the rods could rotate inside their nodal knuckles. That’s what happens when you remake from recycled scrap. It may work with a node fix but likely a redesign to bar instead of rod profiles is best

So after going over the data… I reckon our average efficiency with a 6 blade setup doubled (13.04%) as compared to a very similar 3 blade test (~6%)

Oh… it’s going to be higher than that… I haven’t taken the 2nd plane offset into account yet…

Up a bit to 13.19% now…

But let’s stop with the namby pamby “I’ve got a kite so I want a fair game” area swept aligned to the wind plane nonsense… In real wind power efficiency / full swept area still getting 11.82%

These data are interesting. The average tension looks to be about 75 kg, so about 750 N. It is quite huge, compared to the 12.5 m² area swept by the 4 m diameter rotor (if I remember correctly), suggesting a thrust (lift and drag) coefficient of a little more than 2 to reach 750 N: indeed 1/2 X 12.5 X 1.2 (air density) X 49 (wind speed looks to be about 7 m/s in average) = (only) 367.5 N.

So I see two possibilities:

-

If the device work as a yo-yo system, we should have: 750 X 2.33 (reel-out speed) x 4/9 (remaining force during reel-out) = 776 W.

-

As I think you don’t want it, the pitch angle of the blades could be modified to provide less tension and more torque.

Yeah, I wouldn’t trust the tension data.

The sensor was bodged onto a ground-station which wasn’t designed with tension sensing in mind.

I might get round to re-calibrating that sometime.

But, yeah, it’s a high tension… which is a good thing for a TRPT.

I’ve been using 11.2 m2 as the swept area (Inner tip radius 1.22 Outer Tip Radius 2.25m)

1.3kg/m3 air density

At 7 m/s wind speed a 11.2 m² HAWT would generate an axial (for tension) force of about 320 N. As Daisy rotor is tilted some lift is added as for an autogyro, the whole force coefficient varying according to the rotor disc angle of attack. The figure 18 page 28 of the document below provides a value of the force coefficient of 1-1.2 with a rotor disc angle of attack of 30 degrees close to that of Daisy. So the tension could be perhaps a little more than 320 N. 750 N looks to be an overestimated value. Beside it indeed tension is good for TRPT but perhaps a suitable balancing between tension and torque could be desired in order to optimize the rotor.