A link:

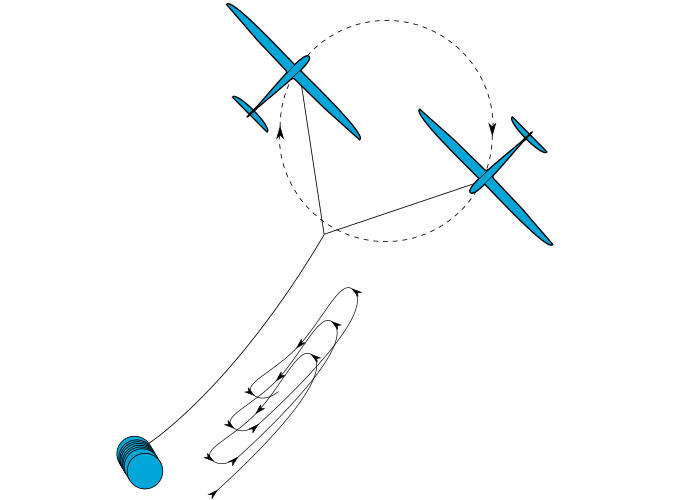

A quote: “Optimal control is one strategy to prepare for the preliminary design of multi-kite airborne wind energy systems (MAWES).”

And a picture below:

Another link:

My opinion below:

MAWES could be a step towards a maximization of the space when the global swept area will be proportional to the tether length. Besides it a redundancy passive safety could be desirable and included in the “optimal control problem (OCP)” if this is not already achieved. Good continuation!