Some extracts:

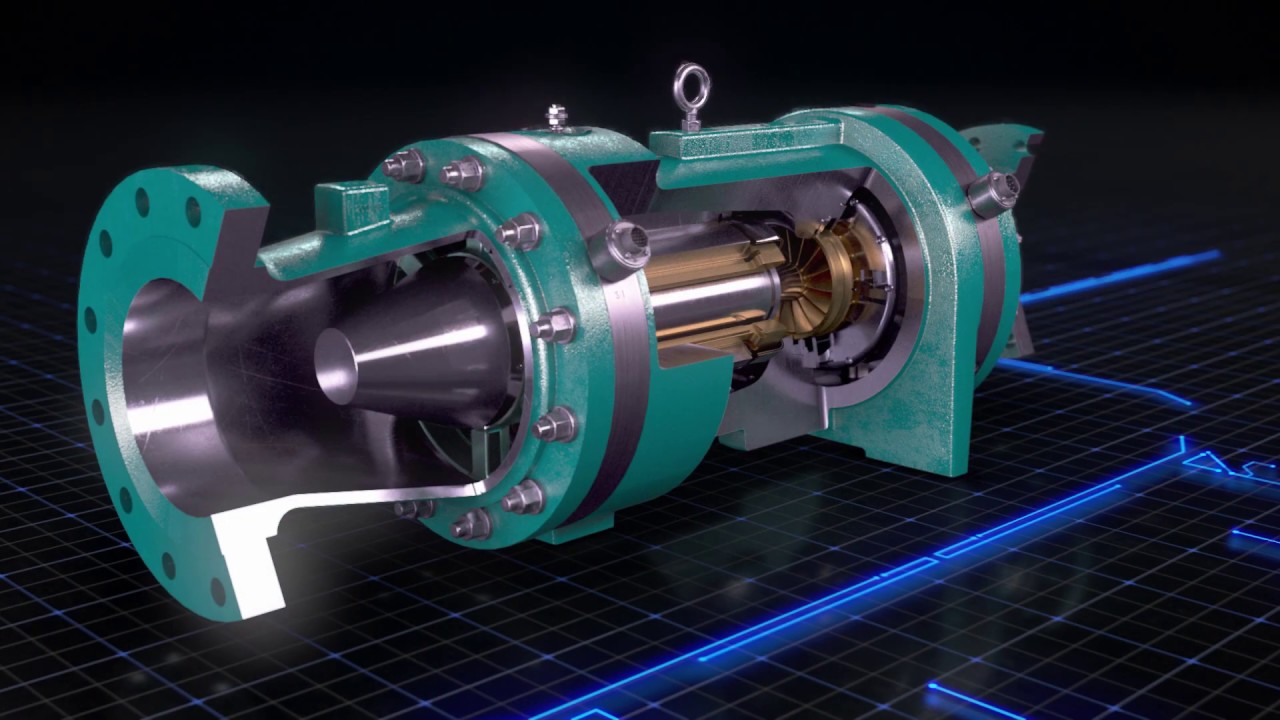

High-speed Motor Operation

Electric machines can be much smaller and have better efficiency when they can operate at a higher speed than the 3,600 rpm limit imposed by 60 Hz power systems.

High Power Density Motor Performance

For applications where light weight is of utmost importance, such as in aerospace and motorsports, Calnetix’s high-speed motors and generators are designed to provide maximum power density while maintaining high operating efficiency and good thermal performance consistent with design requirements. An example of a power dense machine that we have designed and manufactured is rated at 100 kW and weighs 7.7 kg in a 2.3-liter volume, which is equivalent to a machine power density of 13 kW/kg and 43 kW/liter. Calnetix is able to achieve such high-power density due to the following:

- Optimization of electromagnetic design, including magnetization topologies

- Optimization of the machine’s L/D (length over diameter) aspect ratio

- Optimization of the magnetic circuit

- Selection of materials, including the grade of magnets, the stator laminations and their thickness, the magnet retention sleeve and other materials

Optimized Performance by Application

Calnetix’s high-performance motors and generators can be designed along with magnetic bearings and high efficiency variable speed drives (VSD) completely in-house. This enables us to achieve the most compact, optimized solution for each application without compromising any inherit benefits, such as high-speed, high-efficiency operation and zero maintenance requirements. The special construction features and fabrication of our high-performance stators and rotors provide some unique benefits, including:

- Optimized stator configuration due to utilizing in-house tools, such as fill factor, end-turn bundle and neutral termination techniques

- High back EMF per magnet volume with high magnetizing efficiency due to the rotor’s ability to magnetically couple to the stator with minimal flux fringing in the axial and transverse directions

- Minimal rotor harmonic currents due to surface mounting techniques that keep circulating electrical paths isolated without loss of electromagnetic or structural integrity

- Minimal rotor air gap and air gap cooling requirements due to high strength composite sleeve that has near-zero losses from harmonic eddy currents

- Advanced electromagnetic efficiency, rotor tip-speeds and industry-leading power densities due to the proprietary technologies in Calnetix’s PM rotors