What is the best modern mechanical means to convert relatively slow power kite traction to high angular velocity generator input? The basic idea is to turn a shaft at high velocity with as small a diameter pulley/sprocket as practical.

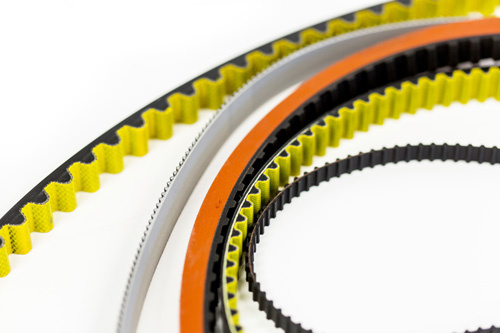

Simple capstan reeling chews up kiteline in a matter of hours or days. Rope-driving is limited in how small a drive pulley diameter has adequate friction. Drive chain lasts far longer, but is comparatively heavy and sprocket tooth life can be low. Belt drives are hard to beat, but which are best?

The newest belt-drive technology is toothed Kevlar timing belts, but not just for timing, by keeping in register (not slipping), but as used for industrial power transmissions at all scales (in parallel as needed).

Short-stroke PTO pumping is favored by similar superior dynamics of short pistons for race-car engines. Just the pumping stroke length needs to be belted; kiteline itself remains outside of the PTO.

Here is a top modern belt and hardware supplier, a sample reference to what is available-

https://www.torontogear.com/custom-belts-power/