Prof Hironori Fuji has previously investigated automated rotary deployment and retraction for antennae in space. I believe he is considering how it may be used on Daisy turbine TRPT’s.

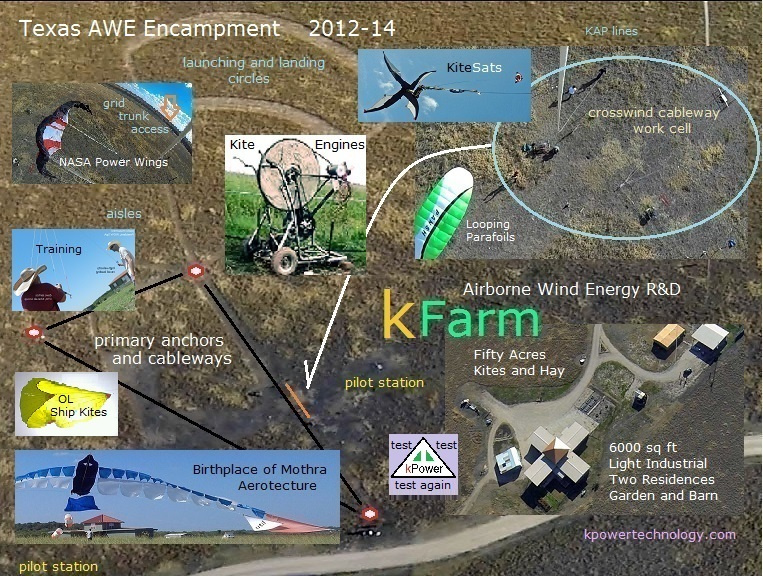

kFarm started as a private airfield and hay farm that became an AWES R&D site for three years. It was shown that commercial hay-farming, cattle-grazing, kites, and aircraft easily co-exist. Integrating kites with general aviation is simply a matter of shared land and airspace, by coordinated operations. Several other AWES programs have validated similar spatial co-operations. Advancing airspace automation will support ever more complex airspace usage.

Land is not used intensively in many remote and rural parts, such as where I live.

Alternative land use wasn’t always a top priority for me …

However, everyone has food sustainability considerations at the moment.

In order to maintain layers of AWES and farming, there needs to be physical protection of the delicate biological and delicate kite materials.

The best way to grow food reliably here in our harsh, windy and cool conditions is inside a polycrub.

At 2m tall there’s not a lot of clearance to worry about. There have been some fairly large arrays of them. The convex polycarbonate shell offers good protection to workers inside. As a bonus the frame is made from recycled fish farm pipes, of which I have removed ~100m from local shores.

Depending on the compliance of your kite device, it could be landed on, bent over and attached onto these shells. Kite rings are pliant when not being flown.

1 more thought. Not strictly land use… Tensile kite lattice frameworks were proposed as an enabler of vertical farming support. Personally I’m concerned the wet mass implications of such design concepts would be a show stopper.

It can be a possibility in some cases. AWES designers, and farmers, could agree on the compatible sorts of AWES and farming.

That said knowing that “A Polycrub is a permanent structure”, the “build typically takes around 50 — 100 hours, depending on size, ground conditions and any internal fit-out”, I would be curious about the price of its implementation on a whole land area of a basic AWES (about 1 km² by taking account of the wind rose). We will likely not see poly tunnels under AWES for a long time…

Polytunnels are a great idea under giant soft kites. Underground concrete bunkers had been suggested in the past for operations under high-mass high-velocity AWES [Old Forum, Feb 9, 2010].

The tunnel form is not only apt to not snag active kites, but could comprise special kite support structures to store and dry kites (solar and/or forced-air), as a giant “spinnaker-sock”, or a long gallery suited to lay out line rigging, or even assemble giant kites on-site. Polytunnels could protect vehicle and pedestrian traffic across a kite field.

The Shetland Polycrub is a particularly outstanding wind-resistant design, based on poly-tube reuse. It could be a ready basis for scaling up Inuit Windsled design. Such structure is inherently lightweight, and could even evolve into airborne service, as an Aerotecture design option.

Commercial pilots sometimes joke, “I work in aluminum tubing”. An AWES pilot might someday be said to work in poly-tubing.

A word of warning in this video to anyone who swears that just by using a network of tethers (that sounds like me) That nothing can go wrong.

If you don’t maintain failed or failing tethers extra load goes to the remaining set.

We all knew this was coming to Arecibo radar telescope … but it’s still tragic to watch science be abandoned.

@PierreB you have performed research into the ground use efficiency of AWES

e.g. how many m2 land is used / kW power generated.

Generally - AWES have a ground footprint and a sky footprint (Wingprint?)

For a given wing-print area an AWES has a safe working permitted ground print area

Relating these areas gives a very simple number to compare systems.

(Kinda like solidity in rotor analysis - rotor solidity relates swept area / blade area )

Single ground station designs may like to claim that ground footprint is minimal and the equation is simply like looking at the solid angle or field of view of their wing in the sky

but fall safety zones are much more important to overall ground use.

For me it seems right that stacked rotors able to work in close arrays will win out on this comparison of land use / sky use…

Anyone got a good reference to better analysis?

@Rodread I had already discussed the land use issue, taking account of your observations.

My model is not yet refined and mainly apply to utility-scale rigid crosswind kites which fly at a low elevation angle, a large part of the tether being close to the ground, this because they accumulate dangers such as the high speed of both aircraft and tether, high mass, high kinetic energy. So in a preliminary approach secondary use is not possible or not easy on more than a perimeter were the tether is the radius, so much for land use that space use.

The footprint is another thing I think and concerns the area of the installations on the ground. For all AWES said area is very small. But for utility-scale rigid crosswind kites, land use prevails. For some other AWES, comprising rotary stationary systems, land (and space) use could be lower as the flight path is restrained and the rigid elements (for Daisy) can be smaller, so less dangerous.

The ideal is that the land use could be closer to the footprint. It would be more possible with stationary or slow AWES flying at high elevation angle. In kite festival we can see that the land use is not much larger than the footprint for even huge static kites which are very close each other and are only separated by their respective wing span. Similarly land (sea) use of crosswind kites can be reduced towards their moving footprint when unities go in the same direction, as for kite surfing competitions, or perhaps AWES using a track with two elongate parts as for NTS video at 1:22 or Kitefarms patent published.

I’m not sure if we discussed this; land use may increase due to the tether going really slack in the return phase for yoyo. If the tether is totally slack the tether will be free falling. So there needs to be a slight tether tension on return. This tension is hugely detrimental to cycle average power. So - weighing pros and cons, you are likely to not want trees, poles, buildings etc in the area surrounding a such AWE installation.

I think the increase in land area use may be substantial enough to include in a model

I think so too, and there are probably other issues that we just don’t imagine yet. That said during the reel-in phase, and in particular if the reeling speed of the tether is high (for example for rigid kites), a lower tension of said tether can be sufficient so that it does not fall, and all the more so that the tether gets shorter during the operation.

![[COLLAPSE] Arecibo Observatory Telescope 📡](https://img.youtube.com/vi/ssHkMWcGat4/maxresdefault.jpg)