Wind Fisher technology is interesting because it allows a Magnus cylinder to rotate while varying the length of the ropes to respond to the reel-out and reel-in phases of the pumping mode, using winches located in the ground station.

This makes it possible to avoid having to bear the weight of the rotation motors in flight, and to do without the electrification of the cables to power said motors.

This is already very interesting for a single balloon.

This would become even more interesting for a balloon ladder.

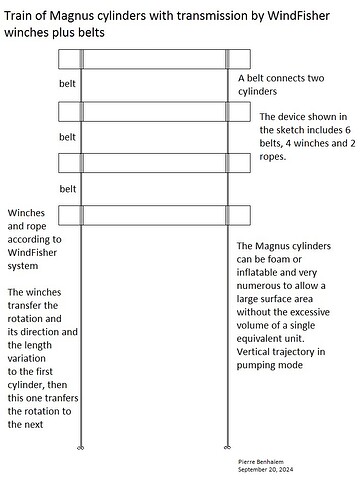

For this the @WindFisher four winch and two rope system would be used for the first balloon (starting from the bottom).

Then two belts would connect the first cylinder to the second cylinder, then two more belts for the second and third cylinders, and so on. A belt connects two cylinders.

Using in pumping mode with more efficient crosswind vertical trajectories compared to basic control. Perhaps horizontal trajectories could also be used, but this would lead to a higher spin ratio of the cylinders, so a higher tangential speed, because the linear speed becomes higher, hence more consumption power (which increases by the cube of the tangential speed).

Of course we would have to see if all this could really hold up to use. A sketch: