DOI: 10.13140/RG.2.2.30719.42406/1

Some ideas and tests for taking advantage of the rectilinear shape of Flettner and Sharp balloons to stack them between ropes have been gathered and clarified a little.

Some points:

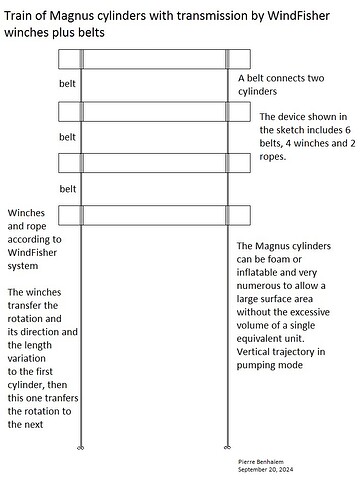

Use as an AWES in pumping (yo-yo) mode with vertical trajectories

In the preprint, concerning Preprint: Towards a gigantic Magnus balloon with motorized belts :

At 10 m/s wind speed and above, a higher rotational speed, even resulting of same spin ratio of 1.21, would not be advantageous due to the power consumption which increases by the cube of the tangential velocity. It is the reason why a giant Flettner balloon with external motorized belts [9] in order to hold the balloon on its whole length was investigated: the large area compensated for the relatively low efficiency due to the limit of tangential speed imposed by the power consumption. But the maneuver of such a giant balloon is not easy due to the high inertia mass. So balloon ladders are preferred.

Luckily, new technologies such as drop-stitch or Shapewave ® [10] would allow cylindrical inflatable balloons to achieve much better rigidity. This makes it possible to envisage a much lower power consumption for the same tangential speed, comparable to what the curve in Fig.13 [5] shows. As a result higher lift coefficients Cl could be achieved.

Conclusion

Flettner and Sharp balloons have a rectilinear shape making them easy to stack in ladders from top to bottom and on the sides. In this way the maximization of space can be achieved, and over very large areas and at height where the altitude wind is more powerful and regular. The reasonable dimensions of the units facilitate their manufacturing and implementation.