Cableways use rope-drive systems. An example of ropeway technology is provided below.

An extract:

One of the strengths of NORD DRIVESYSTEMS is the especially compact design of the UNICASE

housing allowing maximum torques of 250,000 Nm possible up to size 15 in relation to the size.

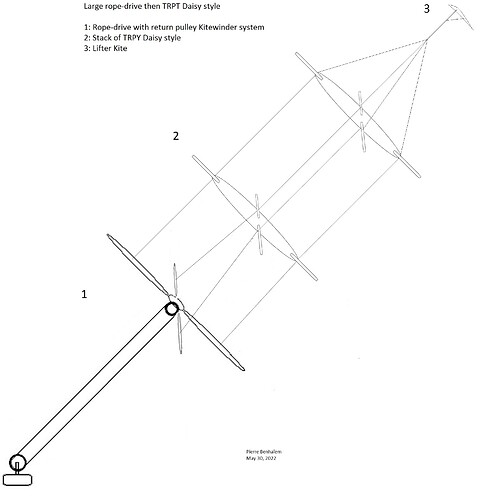

250,000 Nm should be sufficient for any TRPT. Rope-drive transmission, including its variants, has no practical limits in terms of length and transmitted power and torque. On the other hand, TRPT could facilitate rotor stacking. Adjustment of the rope-drive with the TRPT could perhaps be better if the pulley and all the rope-drive system are relatively larger to improve torque transmission:

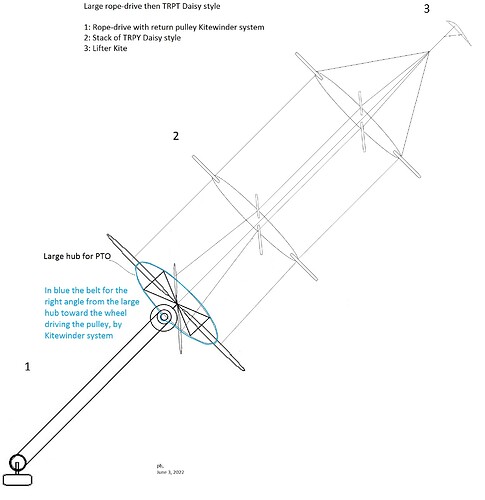

Edit: I add a sketch where the hub is far larger for a better PTO (TRPT torque transmission towards the rope drive via the belt (in blue) for the right angle (Kiwee system, sorry for my poor sketch) between the large hub and the perpendicular smaller pulley via a driving wheel. That said I don’t think that could work well. The idea is (was) to combine the advantage of the length of rope drive transmission, with the possibility of stacking the TRPT rotors.