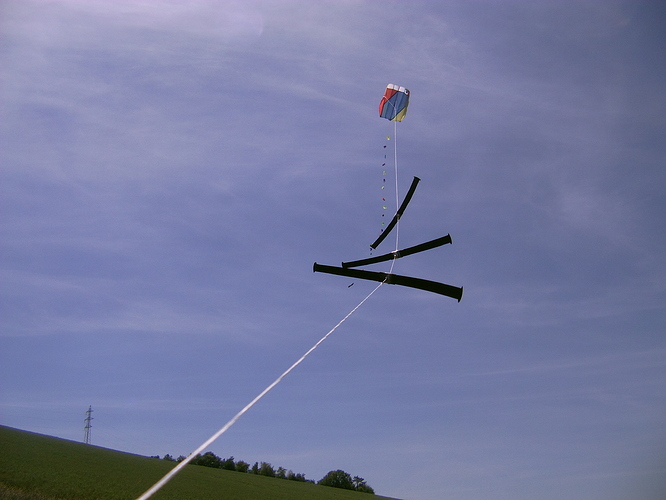

Some experiments with a tiny 0.2 m² pilot kite with three 0.555 m diameter rotors coming from three gyrokites and sweeping a disc of 0.241 m² each. I think a use for yoyo mode would be difficult due to the requirement of starting rotors.

However, the assembly could maybe provide a complement of thrust at high altitude by using many rigid elements with a long service life and could perhaps be usable for scaling a pilot kite for Daisy rotors. But this system of lift can have some limits: on the second part on the video the rotor 1 (which is closer to the kite) and the rotor 2 pull very strong. As a result the elevation angle is lesser until the rotor 1. So stacked complete gyrokites could allow to maintain the elevation angle, while rotors alone could not, or would require a larger pilot kite.

Rotors (and also the pilot kite) with a higher L/D ratio would be desirable. For now the elevation angle is only about 45 degrees for the pilot kite, and from about 20 degrees for the two rotors at full rotation speed due to their disc drag, to 30-35 degrees at lower rotation speed or without rotation, mainly due to their (low, 40 grams per rotor) weight. Some more precise measures would be useful. The elevation angle of this gyrokite is about 35 degrees.

On the photo below, the rotors don’t rotate.