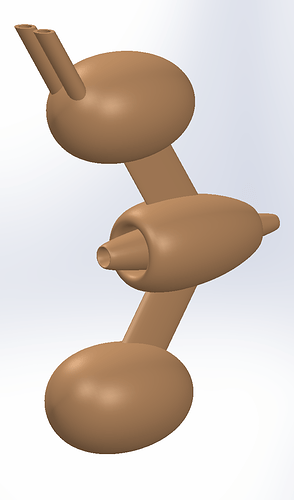

Inside the central ovoid here there are 2 rings that go around the tether that the pod rides on. Also there is some clamping mechanism that clamps the ovoid to the tether when the kite moves downwind and just before it reaches the ground station.

The rest of the assembly is connected to that central ovoid with a bearing that allows the assembly and with that the kite to rotate around the ovoid and the tether, or you leave out the bearing if you decide you don’t want that. The pod needs to be small to be able to go around the pulleys, so extra elements like batteries, electronics and motors go into the other ovoids. You want to preferentially put the weight in the pod instead of in the kite, so you could for example try to fly with two kite tethers like shown here instead of one.