I don’t second the prediction that a large radius rotaty rig (TRPT?) will have scaling issues. A larger radius rig will rotate slower but the size if the shaft grows proportional to reduction in speed.

Lower angular velocity is a critical scaling issue, adversely impacting both capital cost and efficiency. Higher angular velocity would be better. Its no neutral factor.

Good similarity case- a low angular velocity paddlewheel is a far more massive, expensive, and less efficient boat drive than a power-equivalent high angular velocity propeller.

There is no engineering design factor that is not scaling sensitive. To presume an engineering factor is scaling-neutral is both “unphysical” and risky.

Prediction- The highest power-to-mass unit will scale best to high numbers.

This paper can confirm it (page 4/8: 400 m² for 2 MW). But theory and tests of pumping kites give far lower values, due to the downwind motion and both the time and the power consumption during the reel-in phase. In theory a 200 m² kite with L/D ratio = 4 would generate about 285 kW during reel-out (power) phase with a wind speed of 10 m/s, so an average power of about half.

And tests on “hydra” (14 m²) with 10 m/s wind speed result in an average of 5.75 kW (table 8, page 44 of https://repository.tudelft.nl/islandora/object/uuid:56f1aef6-f337-4224-a44e-8314e9efbe83/datastream/OBJ/download). A 200 m² wing with the same features would give an average of about 80-100 kW.

Its quite normal to estimate numbers loosely without excess precision. If needed, simply raise the rated wind velocity to match a desired number. 15msec is not unreasonable. Let the Hydra test be a data-point rather than a final determinant of what a 200m2 kite at 500m can do.

The 200m2 size was chosen conservatively based on being far easier and more certain than SkySails hoped-for 1000m2 unit. I am not ready to adopt 1000m2 as proven, compared to all the KiteShip and SkySails wings closer to 200m2. All this is “solid” to me, since Ship Kites is where I started in AWE, under Dave Culp, who also insisted that high L/D was the wrong figure-of-merit.

No surprise that new developers easily overlook what DaveC learned by being 20years ahead of everyone in power-kiting. No mystery why the massive Inuit WindSled flies an NPW to cross ice caps, nothing better exists yet. Soon its going to be generating its electricity as well, by rolling a wheel-gen. The other kites can stay home.

The results I quoted prove that power kites are good for traction, but not for power generation, at least in pumping mode.

That’s strictly incorrect. Traction power is power.

This is strictly correct. Traction and power generation are not the same.

There is no point in playing with words. The data I have provided show that with the same wing area, power generation is 10 times less than traction power.

This is quite factual, not “playing with words”.

Traction power is a valid subset of all forms of power. When Watt defined power, he used horse traction power.

Its also necessary to subtract generator loss to calculate a kite’s actual power rigorously.

No, we speak about mechanical power, the generator loss comes after.

Agreed. The error is to presume traction power is not power-

PierreB: “The data I have provided show that with the same wing area, power generation is 10 times less than traction power.”

The Arctic sled kites folks haven’t planned to design a drag generator yet.

The npw will need a smaller loop radius to rotate a rig as fast as a higher performance wing. The npw rig will be generating much less power.

I’ve tried this. Ram air vs rigid foam. It has been measured and published on this forum.

This thread is scaling by number.

What other non reciprocal, non line running multi-kite rigs can we devise?

It is likely yours. I said:

The Inuit WindSled team is in fact in current discussion with three AWE players on adding wheelgen power (KGM, UC3M, kPower). The Kiteboard EV is in fact intended to test key ideas hands-on, prior to freezing a specific WindSled design that KGM is working on.

The way for low velocity wings to develop high angular velocity is to pull a belt drive on a small diameter shaft. kPower has several groundgen prototypes that use this method. One can also turn vehicle wheelgens at fairly high angular velocity, like electric train-track AWES schemes.

The Kiteboard EV works this way in regen mode, via its toothed Kevlar drive-belt. The wing is an NPW.

Reeling/pumping downwind is a terrible way to use a great low L/D power kite. SkySails uses up a lot of its raw power advantage over all the hot kiteplanes by its slower higher-drag return cycle. Reeling/pumping crosswind-only is the superior way to harness a power kite.

These basic principles are favored from unit-scale to scaling up in large numbers.

True avg. generation power of the Hydra given in Table 8 was 13.8kW. Pierre only considered total upwind-downwind pumping-cycle avg power, with high retraction cycle loss. Therefore, the estimation of a 200m2 power kite as a nominal to peak-rated MW-class device is not so unrealistic for its pure crosswind peak performance. Dimensionless tether-drag is also lower.

Further, 12msec wind at 500m high is a reasonably low rated velocity, compared to HAWT wind 100m high, often rated to near 12msec.

Its also ok to presume a somewhat larger kite, like 300m2 as a MW-class unit, the primary point being not to presume 1000m2, as a multi-MW wing, is so practical as smaller sizes already proven, for high unit-count kite networks that can approach GW unit class as metakites.

Downwind reeling is a terrible choice of AWES architecture for power kites. Payne and McCutchen USP3987987 crosswind reeling is the better choice.

5.75 kW is the average value given on the table 8. So Pierre considers nothing for that. From this value it is not too difficult to deduce that a similar 200 m² power kite would be a 60-100 kW unit at 10 m/s wind speed, and 100-170 kW at 12 m/s wind speed.

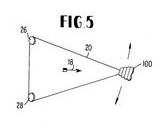

Other arrangements such like  (US3987987 Fig. 5) do not change the fact that the kite generates power when going downwind, flying crosswind or not, with reel or with pulleys.

(US3987987 Fig. 5) do not change the fact that the kite generates power when going downwind, flying crosswind or not, with reel or with pulleys.

Pierre,

Just making it clear to readers that the average power of TUDelft’s complete reeling cycle is far poorer than the average generation power of crosswind motion. Even the TUDelft reeling generation phase is sapped by giving up ground downwind.

I consider Payne’s (and Pocock’s) original crosswind motion assumption to be the better design standard, and its also Hadzicki’s chosen load motion in Lang’s 2004 Drachen AWE coverage, and then Goldstein’s choice a few years later. kPower has always been in this camp.

Its true that fans of Kitepower, Ampyx, Kitemill, and other copycats see downwind reeling as a natural assumption, rather than poor AWES design to be avoided.

The average power generation (reel-out) phase value is 13.8 kW, but the average power value is 5.75 kW, which is the number to take into consideration.

Payne’s crosswind motion should be studied but I think the only real difference in terms of efficiency with reeling (yoyo) mode is the almost continuous alternation of the delivered power.

Imho the Scaling in numbers rather than size topic is the siamese brother of the Scaling by size topic.

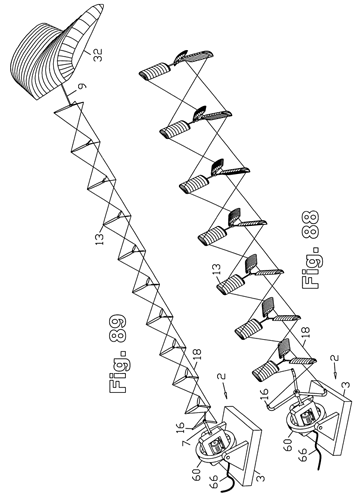

Yes, and some variants (US6616402, figure 88 for example) of SuperTurbine ™ that are discussed make a good approach of both, although I would prefer a single larger rotor because of a supposed easier management of takeoff and landing and flight operations.

SuperTurbine blade motion is not crosswind to the degree that its axis tilts toward vertical to reach upper wind. The blades have upwind and downwind cycle loss accordingly. ST shaft scaling is especially square-cube limited. The shaft is anything but a “kite made of kites”. This is an especially poor choice of Metakite basis.