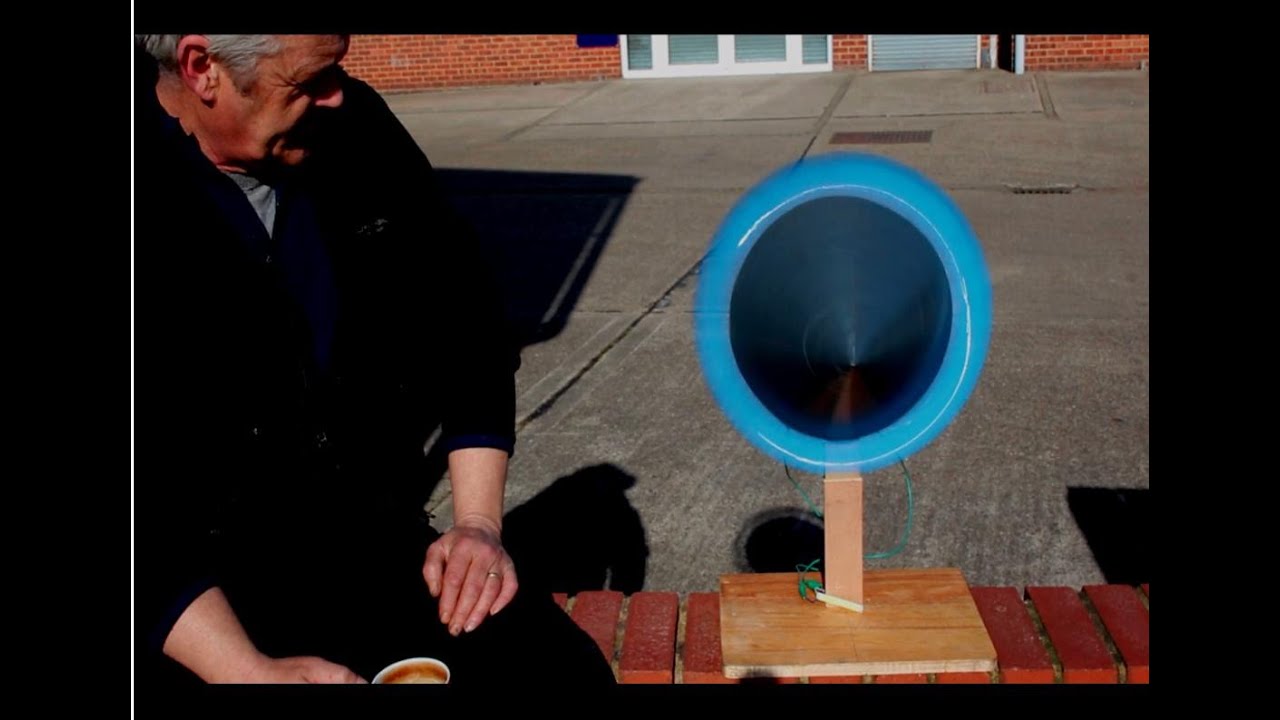

Got to admit if you were in a pinch, realised your had the tools and materials. You would be able to get something. Fairly sure calling it a daisy turbine, is just what it looks like to him. For a back yard bodge , and £50 at your disposal. I think it an excellent in ya face. Opt to carge your mobile phone. Sure the  flags are there for the guys peeking around the corner. Thinking eh oh what’s he up too? Frankly it is a minefield for the unknowing. His is just a Turn of phrase speaks, and what come to mind. Not quite the pipe and slipper engineer. There is Liberal use, of the fair use clause. Stone sour, through the glass. comes to mind here. We’re all look through that glass. Like peering through a shop window. Remind me of a story I got told at when I camped at Corfe castle. once a kid witness a roast sucking pig we had at show. and ended up calling it an elephant. Potato patato thing. Honestly quite amusing.

flags are there for the guys peeking around the corner. Thinking eh oh what’s he up too? Frankly it is a minefield for the unknowing. His is just a Turn of phrase speaks, and what come to mind. Not quite the pipe and slipper engineer. There is Liberal use, of the fair use clause. Stone sour, through the glass. comes to mind here. We’re all look through that glass. Like peering through a shop window. Remind me of a story I got told at when I camped at Corfe castle. once a kid witness a roast sucking pig we had at show. and ended up calling it an elephant. Potato patato thing. Honestly quite amusing.

It’s called harvesting wind energy by the teaspoon.

Very clever Pierre! On the one hand, I’ll give the guy points for an interesting use of a cheap pack of plastic spoons. On the other hand, such a rotor would be more attuned to a directed-flow water (hydro) turbine than an open-flow wind turbine. Reminds me of a sideways version of a pelton wheel, which work best in high-head directed flow hydroelectric turbine applications. Probably a switch to stainless steel spoons would be in order. In windergarten we learn directed flow wind turbines constitute a poor use of material and so have never caught on. Oh well, people who skip class in windergarten often produce such complete windsanity. But hey, all you need are some leftover plastic spoons! Just keep it in the dark, so the UV from sunlight doesn’t turn them to dust.

He already made one and mentioned it was a sod to balance. He been doing a series of thing since things. ever since the Covid outbrake.

He was just showing people how cheaply and easy it could be done. The polycarbonate only needs electrostatic plating and your all good for a few years. It is common practice to plate plastic with a thin layer of metal. I had a torch once I thought was metal. but it had been plated. Would be great for batch production. He also been looking at triboelectric TENG. Combining them and you have a good optimisation. Triboelectric Nanogenerators - an overview | ScienceDirect Topics The good thing about the TENG is power output increases with surface area. Simple as conductive ink and clear coat. I have been wanting to run the idea by you and the others on awes. Seeing the size of the kites and fix wings thought it might come in handy.

I wonder how that is done, how thick the plating is, and how durable it is.

You can buy them already “plated” to look like metal.

High-class plastic "silver"ware… ![]()

Not an answer to the question. And my mild interest is of course also not in spoons but in plating parts I make myself.

How to Electroplate 3D Prints … (the shiny way)

Heavy ion deposition or pulsed lazer deposition is a method widely use. From what I remember thickness is related to the amount of time it’s been place in the ion chamber.

The parts are then give a static charge before a high voltage arc or lasers. are use to evaporate the metal to plate the parts. It heavily use in aerospace industry. Often it’s used on mass to plate 1000s of parts in an instant. I’ve heard 0.4mm being bounded about. The torch I had sat in my pocket solidly for 5 years. about 3 of them it resisted the daily abuse. Before showing signs of ware. For an active chap like myself that was impressive.I had no idea it even was plated till the plastic started to show through. Never had a go myself nor would I know how much it cost but it’s is a very neat process.

See for example

And now, back to our regularly-scheduled show…

Speaking of spoons, somehow Youtube just spoon-fed me this:

Harmony Turbines

Hmmm, somebody didn’t go to Windergarden!

(Especially the investors! - ouch!)

Doesn’t exactly make power yet - well they’ve only been “working on it” for 4 years.

Typical - vertical-axis people often wait years before someone forces them to attach a generator - they hate that step. They are happiest in the “Look, it spins!” phase.

But they raised a couple hundred thousand bucks, and now have a shop with machine tools, and have apparently hired a few people.

They show a unit being truck-tested - wow, sure spins slow for how fast the truck is going!

How fortunate they had a 3-D printer or they might never have gotten started!

The miracle of 3-D printing! How can they possibly fail?

Thank God for them or the Earth might fry.

I will stop here and let you guys debunk it!

To begin: This machine is

- a lift machine

- a drag machine

Like Magenn, a rotary AWES based on drag like Savonius type, but with the difference that the turbine placed on a horizontal axis also generates lift by Magnus effect, which allows it to float in the air, also taking into account the additional lift by helium inflation.

Cool Video, Pierre!

Wow, looks like they’ll be shipping their 4 kW product in 2007.

I’m excited.

For newbies or people not yet born back then, Magenn was the original “poster-child” for AWE, appearing on endless magazine covers and websites. Even NASA was using Magenn images to promote… something.

Of course, I was there protesting that it was just “idiots, idiots, idiots”, but who listens to me?

A true work of art!

It does however show how one may go about executing and funding a development phase of a wind turbine

The bodgineering on this guys daisy turbine is going well

it keeps the same output 10v over a wide range of alignment to the wind. So the speed is constant.

In other words - the blades can’t run as fast as they want to because of high solidity.

Who knows

That property of reliable speed across a range of alignments might well suit an AWES.

More likely an auxiliary power supply on a system where a tangential alignment is not optimal.

O the joy of a future where electricity is provided by a huge multiple of plastic teaspoons in my garden. The future can’t come soon enough

Anyone have a lifecycle analysis of these units?

He does seem serious though. I dont see why, when you could have proper renewable energy delivered at all outlets in your house, at a really affordable price…

@PierreB @tallakt @tallakt @Windy_Skies @Rodread @dougselsam

Do I see a design war kicking off?

If so?

Considering steam bending a is thing. Hazel or willow are good resources.

So if you do have a windy garden. This might also do the trick.