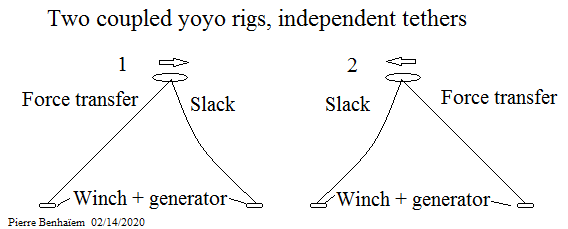

Disconnecting the tethers avoids simultaneous traction on the two elements on the ground, in a similar way as for Tri-tether plant with independent stations. However, the device shown below does not adapt more to changes in wind direction than the device shown in FIG. 5