(PDF) Wind turbine with rope-drive transmission via Magnus effect-based balloon

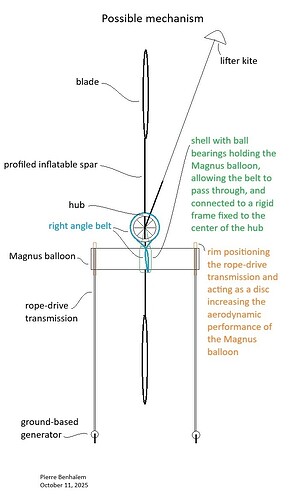

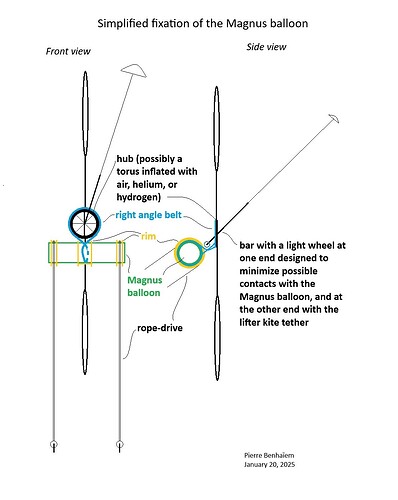

Airborne wind energy system (AWES) including a wind turbine with rope-drive transmission, where the main pulley is replaced with a Magnus effect-based balloon.

Introduction

This preprint intends to improve the potential of scalability of an airborne wind energy systems (AWES) including a wind turbine whose transmission to the ground-based generator is done by rope-drive [1 and 2], named “Kiwee”, avoiding supporting the highest mass (generator) aloft. That said the pieces for the transmission settled in the middle on theturbine, above all the “right angle” pulley [1 and 2] can become heavy when scaling.

Possible solution

So, it is planned to install as many of these parts as possible (fixed support and rotatingparts) as inflatable elements. In first, the “right angle” pulley [1 and 2] becomes a Magnus effect-based balloon, with the advantages of both lightness and aerodynamic lift, plus aerostatic lift when inflated with helium or hydrogen, or air heated by an electric cable [4].(PDF) Wind turbine with rope-drive transmission via Magnus effect-based balloon. Available from: https://www.researchgate.net/publication/396444253_Wind_turbine_with_rope-drive_transmission_via_Magnus_effect-based_balloon?channel=doi&linkId=68ec0f0002d6215259bb2893&showFulltext=true [accessed Oct 12 2025].

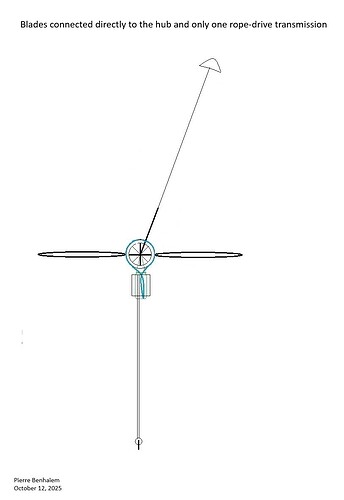

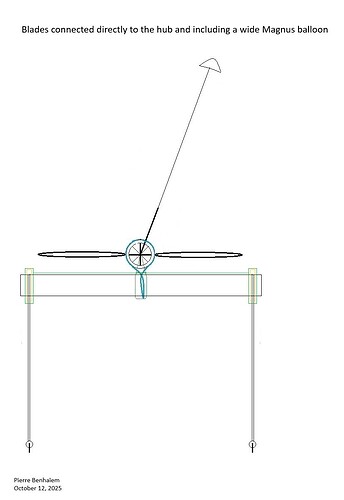

Some sketches:

Wide Magnus balloon = more wind shadow but also more lift and more turbine protection.

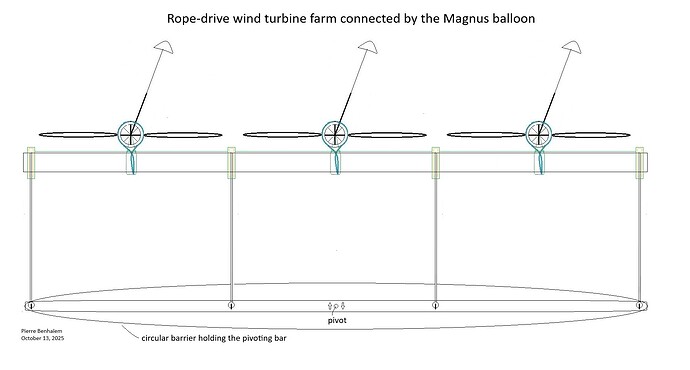

Rope-drive wind turbine farm connected by the Magnus balloon

The Magnus balloon serves as a transmission pulleys, lifter, and wind turbine separator to maximize density.