I’ve made a demonstration video of the simulations showing the different effects

It looks like TRPT systems with straight lines between rigid polygon layers resist over-twist better than TRPT systems with straight lines and trailing torque oriented lines between rigid polygon layers

This work is most closely related to the rotary power transmission designs in

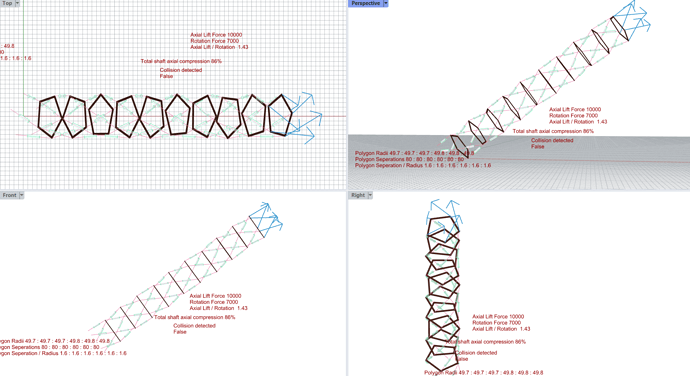

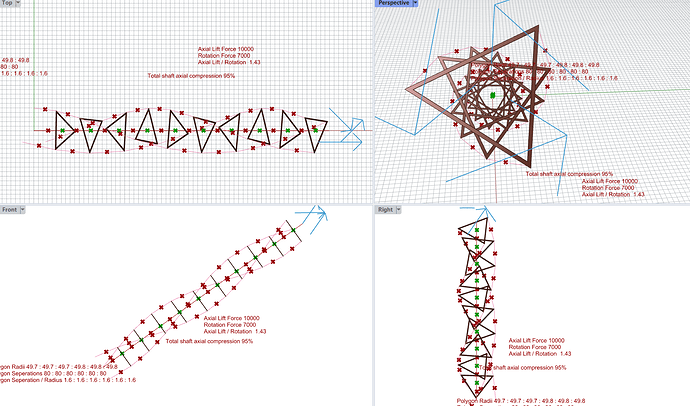

One effect which stands out for me is that when the rigid polygon layers are triangular …And the models are force settled… The triangles in the layers seem to become significantly displaced from their original axis in a spiraling pattern. You can see the overall shaft curve in the pictures in the previous post.

A spiral or bent spinning shaft like that will not be stable.

Adding 2 more sides to the triangle polygons to use pentagons looks to significantly smooth out the resultant deformation…

This similarly tensioned & torqued shaft appears to have less torsional deformation.

Seems like I am wrong again and fooled easily by optical illusion.

The centre of the triangle volumes is right on the centre line. also

I measured the average of the centre of the tx lines. The average point is basically right on the centre line. = No deviation of the triangles

It may not be so inherently wobbly …