Beside the interesting study from @gordon_sp, the problem I see is the requirement of devices such like angle pulleys in order to assure a correct transmission from the tilted propeller of type HAWT. The more it scales the more weight penalty occurs. Moreover a farm of these devices would be difficult to manage due to the risk of collision with serious damage.

So the rope-drive can perhaps be more suitable for horizontal VAWT because it naturally assures both tension and transmission without supplementary devices. Moreover a farm of horizontal VAWT can be more easily managed, the possible collisions leading to minor consequences, as for AWES farm in bumper car mode.

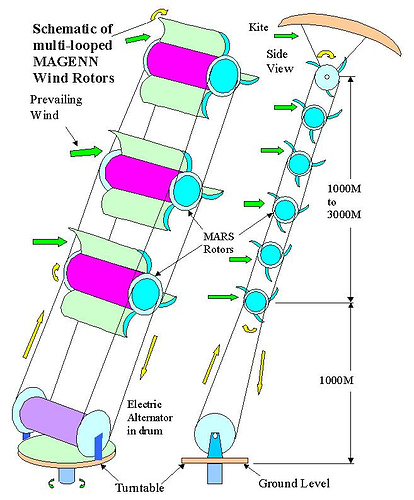

An example is given on http://www.energykitesystems.net/0/Magenn/ , design by Harry Valentine:

Darrieus, Savonius (like for the design) and other horizontal VAWT could be used. In all cases the lower efficiency by unity could be compensated with both a higher use of the space and a simpler rope-drive transmission system.