OK here is the booklet I ordered from the U.S. Government Printing Office way back in the 1970’s.

Wind Machines - Frank R. Eldridge - Google Books

If I seem to know everything about wind turbines, this is why. I’ve known everything in this book for my whole life. Nearly everything we talk about in these chit-chat groups was already known back in the 1970’s, or actually way before that.

In this book, you can see the progress from vertical-axis machines thousands of years ago, the first horizontal-axis turbines using “Daisy” type rotors with multiple kites in a circular path connected with lots of lines, to windmills with real airfoil blades becoming the main non-animal source of industrial power for Europe for hundreds of years, to early electrical turbine including early Danish designs reminiscent of the KiteX portable camping wind turbine. The booklet predicts the entire subsequent evolution of wind energy, including the nearly ~20 MW machines now beginning to be built and run.

On page 22, the concept of “crosswind” devices is largely dismissed, without even describing what they are, which seems weird. The points to note, for me, are:

- “Crosswind” devices (meaning I guess, non-aiming devices with sails mounted on cable loops) had already been dismissed as not efficient, way before Loyd’s Crosswind Kite Power patent in the 1980’s

- Apparently, nobody noticed that horizontal-axis turbines are actually 100% crosswind, even more so than “crosswind” devices, since the wind direction is always changing, and horizontal-axis turbines normally maintain aim into the wind!

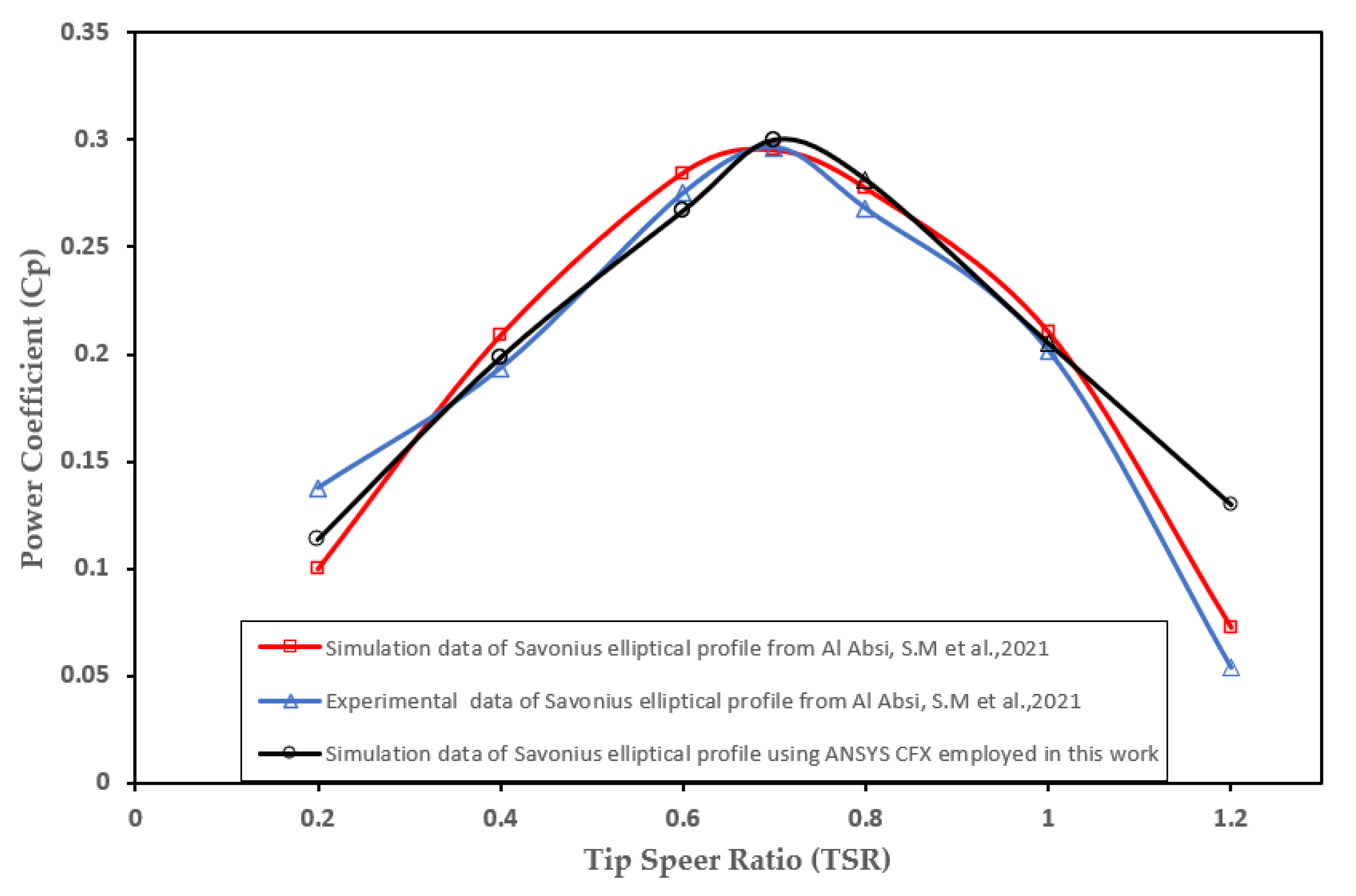

On page 55 is that old, standard diagram of the efficiency of the various types of turbine, at various TSR’s (tip speed ratios). You can see that the Savonius was tagged with a max Cp of over 0.3, while the American Farm Water Pumping Windmill was labeled with a Cp of only about 0.1.

More modern versions of this chart reverse this labeling, giving the Farm windmills the 0.3 Cp, and Savonius the 0.1 Cp number:

Efficiency trends for wind turbines types (í µí¼ í µí±¤ ) versus tip… | Download Scientific Diagram (researchgate.net)

Comparison of aerodynamic efficiencies of common types of wind turbines… | Download Scientific Diagram (researchgate.net)

There has always been an emotional debate over when, and why, these number assignments on this now-ancient chart have been swapped, one for the other, and which is accurate(?). Of course, the Savonius devotees always complain that the labeling on the chart was sneakily reversed in order to stamp out the competition for regular wind turbines, while the farm water-pumping people seldom worry about it, because they produce machines that have always worked well for their intended use, and nobody cares much about the details.

Because the farm water-pumper has high rotor solidity and resulting low tip speed ratio, it is considered a drag-based machine, even though it uses blades rotating across the wind. The reason for the low efficiency is the low speed, which gives away half of the possible kinetic energy (proportional to V^2), to wake swirl. So it is said by those familiar with the numbers, that the farm water-pumping rotor has about half the efficiency of a regular low-solidity, high TSR propeller-type rotor.

This would logically place the farm water pumper at a max Cp of around 0.3

And we all know that with the Savonius buckets traveling downwind, thereby cutting the relative working windspeed in half, minus the energy wasted pushing the buckets upwind, combined with the fact that only half of the machine is predominantly producing, rather than using energy, even while doubling the officially-recognized swept area, it would be difficult for a Savonius to operate “efficiently”, according to offical requirements for such measurements.

That would logically suggest the Savonius might enjoy a Max Cp of around 0.1

So my opinion is the labeling was accidentally reversed on the old chart from the 1970’s, and was subsequently corrected. But the question remains, why is this old chart seen as even 100% factual, with the only question being of which label to attach to which curve, when so many decades of measurements have been produced since then? Weird, huh? Well, that is a window on human nature. Once something is stuck in our heads, it is nearly impossible to replace. Think of official “religion”…

Maybe BOTH curves are a little off. Maybe they both have about the same curve! But I’m gonna go with a Cp of 0.3 for farm water-pumpers and a Cp of 0.1 for Savonius, because that seems to be what everyone who knows anything (“real wind people”) agrees with. The main “advantage” to Savonius turbines is they appeal to people with zero knowledge of aerodynamics and “lift” because “any idiot” can intuitively understand how they work. Period. So, who likes them, and for what reason? Idiots, because they are idiots! Not that complicated! (assuming, of course “real wind people” know what they are talking about…)

The funny thing is, after all these years, people are STILL photocopying and quoting this now-ancient chart. In all these years, nobody has made a new chart that differs from this.

OK now, I’ve gotta go get some oil drums. Because Pierre has discovered that Savonius turbines have a Cp of 0.3, and I need to start building them!!!