Is an electrically heated balloon support for AWES possible?

How much power do we need for enough hot air?

There’s LTA expertise on this forum, so I’m naively hoping this topic can be quickly resolved.

Lets say we wanted a lifting device for just 3000N of constant pulling force, to lift an AWES top end.

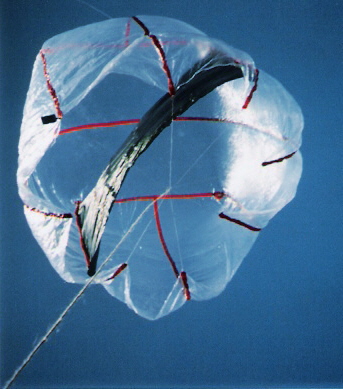

We choose an LTA kiteoon arangement… Such as this by Lockheed Martin, forecast to be in use servicing 20 ton payloads by 2019. Ahh so … ohh! Anyway…

Let’s also say we don’t use helium, instead, we use actively heated air.

Let’s also say we can supply the kiteoon with electrical power from our lifted turbine or grid power through anchoring lines…

Question

What would the likely electrical energy requirement be to heat air & maintain this 3000N line pull?

Is this feasible? Industrial space heaters >30kW mostly change from being electrical to LPG or Diesel… Is there an energy density, electrical to air heat transfer law which can’t be resolved or is this a design problem?

From https://en.wikipedia.org/wiki/Hot_air_balloon

The typical burners- produce 2 to 3 MW of heat

That’s for a standard open-bottomed person lifting balloon.

For buoyancy

The total lift for a balloon of 100,000 ft³ heated to (99 °C, 210 °F) would be 1595 lb, 723.5 kg. Double our requirement.

For typical atmospheric conditions (20 °C, 68 °F), a hot air balloon heated to (99 °C, 210 °F) requires about 3.91 m³ of envelope volume to lift 1 kilogram (62.5 ft³/lb).

3.91 * 300 =1173m3 for our balloon maintained at 99 °C with only hot air lift.

So we need to know the very basics…

How efficient and lightweight could we make the internal air heating element with electrical heating?

How insulating can we make the skin - skins?

How much control of lift does a kiteoon offer? vs safety, vs reliability, vs complexity…

Would heat being lost to the atmosphere be considered counterproductive?.. likely yes. Although if the energy is initially extracted from the air… fair’s fair.

Standard balloon envelopes lose a lot of heat… There are improvements.

https://www.festo.com/net/SupportPortal/Files/42096/Iso_Ballon_en.pdf (See relevant expert… Alexander Bormann)

Balloontype: M - 105

Volume: 3000 m3

Envelope weight: 158 kg

Passengers: 4 – 5

Fabric insulation: aerofabríx® [Iso] 45 | 4.5

Thickness: 6 mm

Specifi c weight: 45 g / m2

Thermal conductivity: 0,0265 W / mK

U value (6 mm): 4,5 W / m2

K Max. operating temperature: 140° C

Brand designation: aerofabríx® is a brand of Dr. - Ing. Alexander Bormann, Berlin, Germany

(Yes the same Alexander Bormann)

According to

UNIVERSITY OF CALIFORNIA,IRVINE

Heat Transfer Model for Hot Air Balloons

THESIS submitted in partial satisfaction of the requirements for the degree of

MASTER OF SCIENCE in Mechanical and Aerospace Engineering

by Adriana Lladó-Gambín

70% of the heat losses are due to the emitted

radiation from the balloon envelope and that convection losses represent around 20% of the

total.

Burner Duty cycle varies from 10 to 28%

The fabric weight is approximately 65 𝑔𝑟/𝑚2, its thickness 0.1 𝑚𝑚, and its thermal

conductivity can vary from 0.003 to 0.04 𝑊/𝑚𝐾 depending on the fabric color and the

temperature [8].

[8] W. Hallmann and U. Herrmann, “Energy Losses, Porosity, Strength and Stretch

Behavior of Hot Air Balloon Fabrics Subject to Temperature Loads and Ultraviolet

Radiation,” in International Symposium on Hot Air Aerostatic Vehicle Technology,

1991.

I guess a larger volume means lower surface area ratio… So, relatively less heat loss. So going big might be attractive but it means a harder to control lift kite component… Kites lift helps to compliment the drag down of the balloon in high wind.

Your thoughts please…

Is an electrically heated balloon support for AWES possible?