200 years is how long a molecule of CO2 stays in the atmosphere. There are way too many there already. So - We have to go to zero emissions. total cut. end of emissions.

I’m still going to fly. I want electric planes. (had a lovely family snowboarding holiday in Austria last week … melted another polar bear ![]()

![]()

![]()

![]() )

)

I’m still going to heat. I want electric heat-pump heating.

It’s bloody windy where I live and it’s similar at altitude in a lot of places. (Austria is wind dead apart from the foehn) The energy density of solar has massive implications for the area we need to use. High wind is massively energy dense.

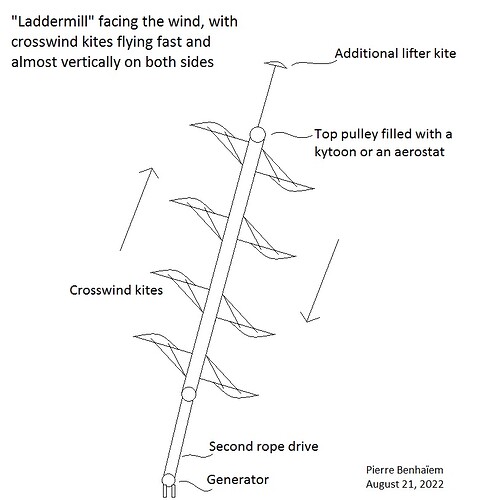

If it’s viable to have massive turbines it’s viable to have working AWES.

Chat about Daisy (A very simple - multi kite - scalable - AWES ) was removed from

The

AWE prognosis .

basically says… AWES could happen if we just pull the finger out and get on with it.